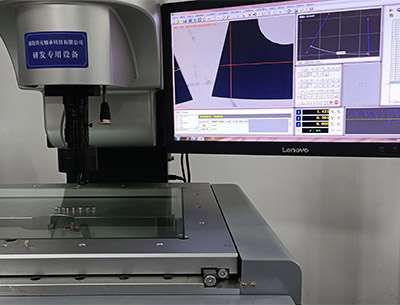

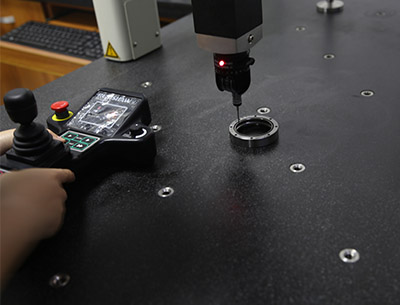

Luoyang Hongyuan Bearing Technology Co., Ltd.(HONB) was established in December 2005, located in Luoyang Konggang Industrial Cluster. There are currently north and south plants, with office and production plant area of 55,000 square meters. Currently, there are over 630 employees on site. HONB focus on researching, developing and manufacturing precision bearings and extension products.

More

ADD:Chuangye Road, Konggang Industrial cluster district, Luoyang city, Henan province, China

ADD:Chuangye Road, Konggang Industrial cluster district, Luoyang city, Henan province, China

Phone:18838816321

Phone:18838816321

Tele:0379-63086103

Tele:0379-63086103

QQ:1553564138

QQ:1553564138

WeChat:HONBbearing02

WeChat:HONBbearing02